Stainless Steel Casters

Table of Contents

Get A Quick Quote for Stainless Steel Casters

Are you looking for a stainless steel casters supplier at a competitive price? Or do you just want to learn more about it? If so, you’ve come to the right place. Based on our decades of caster experience, leading ultimate service, in 1-3 business hours you will get your required wholesale price and information, including all shipping costs from China to your destination, no matter it is a bulk order or a small order, even if it is 10 units, we can also check the turnkey price for you, so that you can compare with your local purchase.

What Regular Stainless Steel Castors Do We Supply?

-

Stainless Steel Casters

Medium Duty Stainless Steel Casters (136kg)

-

Stainless Steel Casters

Medium Duty Stainless Steel Casters (110kg)

-

Stainless Steel Casters

Medium Duty Stainless Steel Casters (125kg)

-

Stainless Steel Casters

Heavy Duty Stainless Steel Casters (450kg)

-

Stainless Steel Casters

Medium Duty Stainless Steel Casters (146kg)

-

Stainless Steel Casters

Antimicrobial Stainless Steel Casters (410kg)

-

Stainless Steel Casters

Impact Resistant Stainless Steel Casters (304kg)

-

Stainless Steel Casters

Impact Resistant Stainless Steel Casters (450kg)

Features and Applications of Stainless Steel Casters

Features

Stainless steel casters have strong corrosion resistance and can adapt to harsh working environments. Stainless steel casters usually use stainless steel plates and stainless steel double beads. In terms of structure, etc., due to the addition of special alloy materials to stainless steel, it is not sensitive to some corrosive chemicals. Even if it works in a chemically corrosive environment, it will not affect its use effect and product quality. Therefore, stainless steel casters are used more in the chemical industry.

Stainless steel casters have the characteristics of wear resistance, low noise, corrosion resistance, impact resistance, flexible rotation, accurate rotation track, strong bearing capacity, many styles and strong practicability.

Applications

Stainless steel casters are widely used in many industries, including the food processing industry, catering industry, medical industry, industrial industry, etc.

Why Import Stainless Casters from Carson?

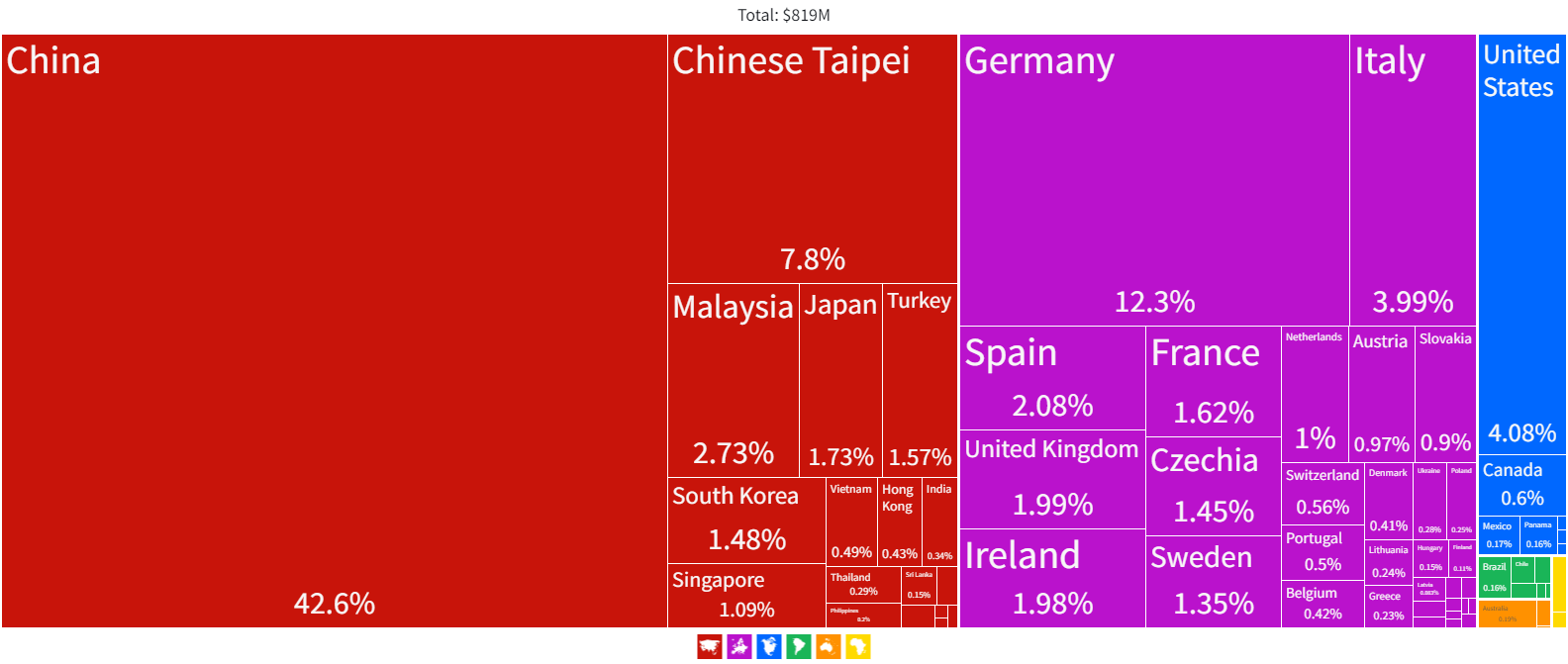

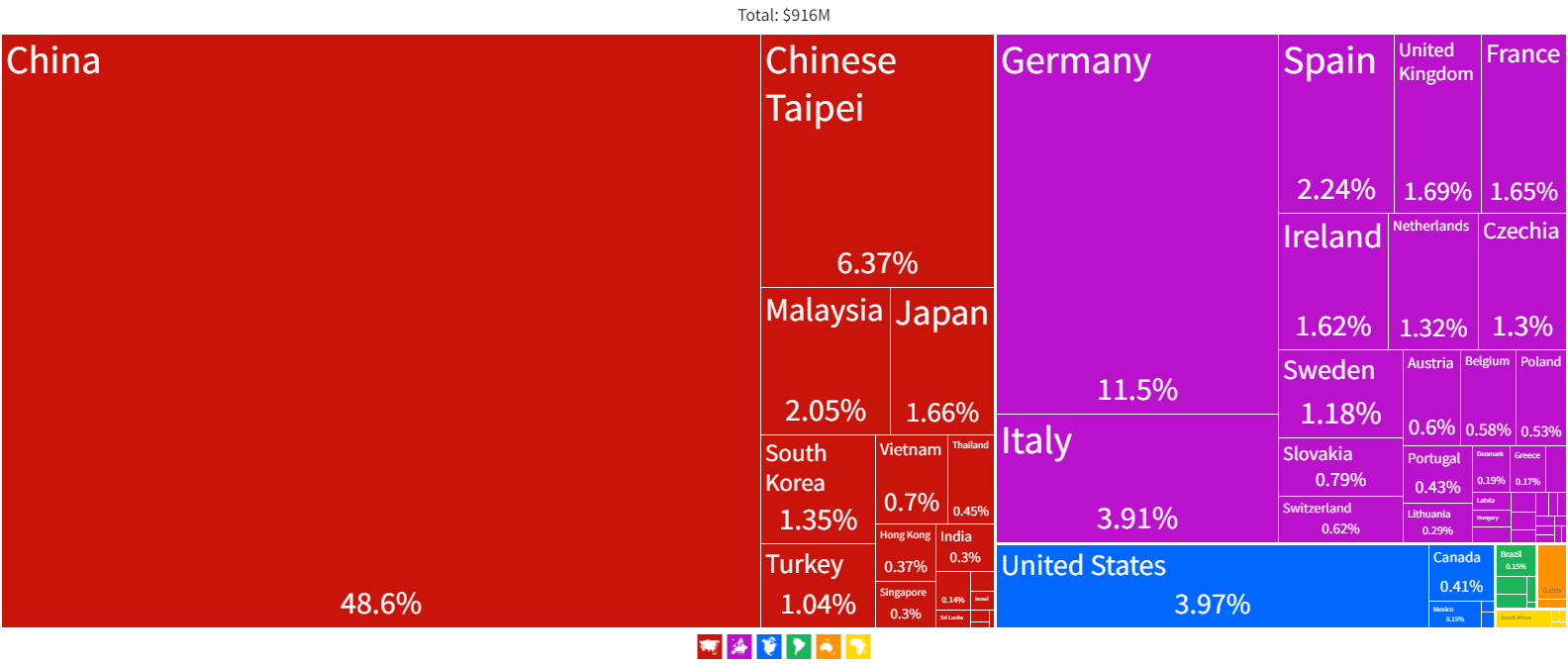

“In recent years, the export of casters from China has reached nearly 50%. And it has been on the rise since 2017 (from 42.6% in 2017 to 48.6% in 2020).” Chinese castors are among the most used products in the market. Some countries even imported all their casters & wheels from China, you can find them everywhere in your country. If you are planning to source caster wheels from your country, why not consider sourcing directly from China? You’ll get the same quality at a cheaper price. Why are Chinese castors so competitive? There are several reasons why this is the case. Here is why:

High-Quality Products

Contrary to popular belief, Chinese products are of really high quality. You have probably heard or maybe even believe that Chinese products are of poor quality. Well, this is not true. Have you ever asked yourself why Apple manufactures its products in China? It surely can’t be because Chinese products are low quality. Apple saw something special in the Chinese manufacturing industry that is why they switched to manufacturing in China. China has the infrastructure to efficiently produce high-quality products.

Mass Production

This is one of the reasons why most people opt to import goods from China across the globe. The fact that the Chinese manufacture goods in large quantities makes the goods a lot cheaper. This is perfect for businesses since it makes the acquisition of products very cheap and the profits quite high.

Accessible Materials

Manufacturing materials are easily accessible in China and at a low cost. This makes manufacturing costs low therefore minimizing the cost of products. For this reason, China becomes the best place to import products from. They have state of the art technology and machines to manufacture the best quality products.

Why Procurement Stainless Steel Wheels from Carson?

Many of our customers from all over the world (such as Singapore, Malaysia, the Philippines, the UK, Australia and the UAE) only purchased casters locally before meeting us. As far as I know, the most important reason is that they think the price of importing casters locally or from other places may be more expensive, because their purchase quantity is not large, and later we changed their minds with facts. And then they all became long-term customers.

Flexible Order Quantity

Support sample orders, and no matter it is a bulk order or a small order, even if it is 10 units, we can also check the turnkey price for you, so that you can compare it with your local purchase.

Quick for Quote

Based on our decades of caster experience, leading ultimate service, in 1-3 business hours you will get your required wholesale price and information, including all shipping costs from China to your destination

Quality is Guaranteed

The factory has passed the ISO9001:2015 quality management system standard and has strict incoming inspection, production inspection process and third-party quality certification.

How to Start Working With Us? Starting with Your First Request!

It’s easy to work with us and find out how you can get it from the process below!

If you choose from the product list on our website, please go directly to the following steps. If you need other styles, please send us an email.

Request A Quote

You can request a quote from our product page, or you can email us directly.

Get A Quote

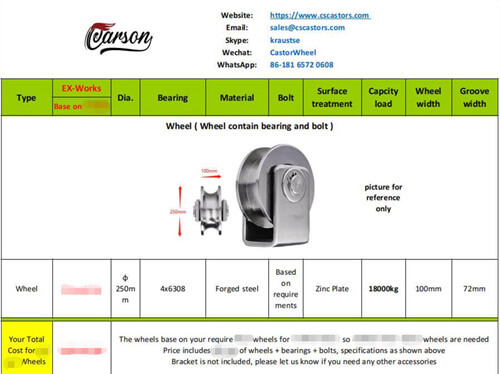

You will get the full product specifications we send and a quote including all shipping costs.

Formal Quotation

Once you confirm the price we will send the official quotation, it will not be changed during the price validity period.

Confirm the Order

It is also supported that you confirm the final purchase and request an official stamped proforma invoice/contract.

Ample Inventory and Flexible MOQ Support from Carson Castors

Most of the regular stainless casters styles are in our catalog with ample stock of materials, which is why we promise fast delivery in 3-7 days.

At the same time, we also work for end users/retail customers, such as heavy casters replacement for manufacturing equipment, office and furniture casters replacement and industrial casters replacement for factories, etc. We can always recommend suitable styles and flexible MOQ for your casters, saving most time and cost for your casters procurement.

Carson Castors Ample Inventory of Materials

Casters are Assembled of Materials According to Your Requirements

How Can We Customize Stainless Steel Castor Wheels for You?

If you have stainless steel castors product in use and do not want our regular style, you can also request our customized service, but it will take longer than our regular style, and there may be additional costs, please follow the following process.

Caster pictures or links you request

Please provide any pictures and links or any information you have about the custom product and we will check and let you know the feasibility.

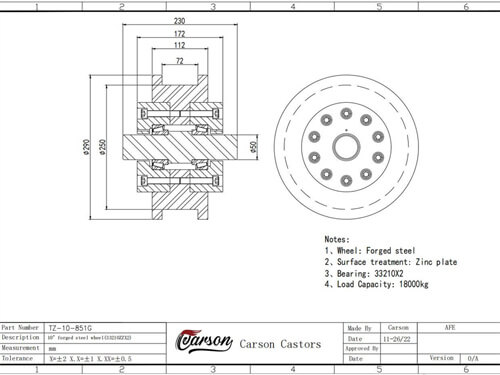

We provide the drawings

Once its feasibility has been confirmed, our engineering team will make drawings for you according to the requirements and send them to you for inspection.

Check quotation

Our Supply chain department will calculate all costs for you regarding customized casters and you will get a full reference quotation.

Confirm the quotation

We will proceed with the order after confirming the quotation. Don't hesitate to start this operation to make it easier.

How will Your Order be Manufactured and Packaged by Carson?

Your stainless steel castor orders manufactured and processed from Carson, will undergo strict quality control, material testing, and pre-shipment testing.

Part of Carson's Production Line

Quality Testing Before Loading

Packing and Loading by Carson Castors

How Will Carson Ship Your Castors Order?

We support most of the transportation terms based on our logistics supply system, common transportation terms such as EXW based on your designated freight forwarder, FOB, CIF by sea, and DDU, DDP by Express Air or Rail to your destination, etc.

Shipping Castors by Express

You can choose EXW, DDU and DDP shipping terms to get your order via DHL, FedEx, UPS, TNT and Airline.

Shipping Caster Wheels by Air

Please provide your designated airport Once you wish to transport by air (airport to airport), you will also need to transport yourself from your airport to your destination.

Shipping Casters by Train

Rail transportation is mainly aimed at European countries. It is more economical than express and air transportation, and faster than sea transportation.

Shipping Castor Wheels by Sea

It is your best choice when you have a heavy order and are not very urgent about shipping time, relatively speaking it is the most economical once you order more than at least one 20 ft container.

What Payment Terms do We Offer for Your Castors Order?

Normally, we only accept Bank Transfers/Wire Transfers to our company bank account, Western Union, PayPal, Alipay and Cash payments. L/C is only for customers we are familiar with and credit customers we are working with.

Bank Transfer (T/T)

Bank transfer is open to all regular order customers and we will provide the company bank account number on our contract

Letter of Credit (L/C)

To become our credit customer, we will open the Sinosure guarantee for L/C orders. To provide two-way protection for our cooperation.

Selection and Use Conditions of Stainless Steel Casters?

When using casters, it is hoped to first consider their use, required functions, and conditions of use (use range), and then select the appropriate type, please pay attention to the following:

(1)Choose the right load bearing.

The possible load bearing mentioned in the product introduction refers to the general load that is easy to move when moving on flat ground by manual operation. It is also a general load that can be carried out for a long time in a safe state. It is necessary to estimate the total weight of the carried objects in advance, and then select the appropriate castors according to the allowed load.

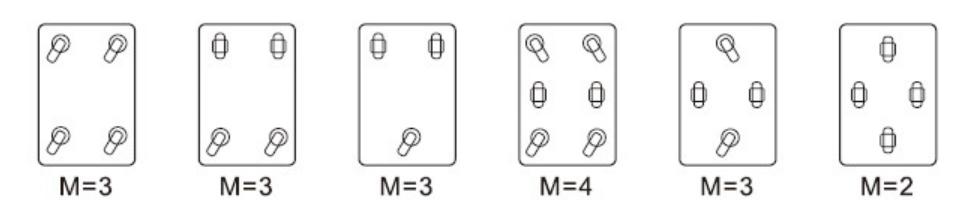

Carrying weight calculation: T=(E+Z) / M

T = required load bearing weight of single wheel or caster

E = self-weight of transport equipment

Z = maximum load

M = number of wheels and casters used

(Location, uneven weight distribution should be considered)

The effective load capacity of the wheel (M) is as follows:

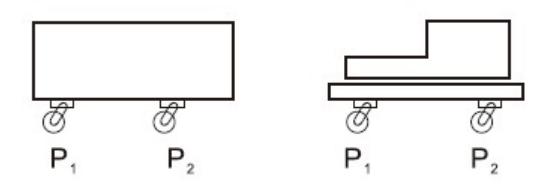

When selecting the load bearing, it should be calculated according to the bearing capacity of the caster at the maximum support point. The specific force support point of the caster is as shown in the figure below, and P2 is the heaviest support point.

When using casters of different sizes, specifications and models, please use the caster with the lowest load-bearing capacity as a reference to calculate the overall maximum load-bearing capacity.

(2)Choose the right bearing

Single ball bearing: The ball bearing made of high-quality bearing steel can carry heavier loads and is suitable for occasions requiring flexible and quiet rotation.

Double ball bearing: In addition to the advantages of the single ball bearing, it also greatly reduces the gap between the left and right swing amplitude of the wheel and the swing amplitude of the up and down, making the wheel more stable in use.

Roller bearings: Heat-treated roller bearings can carry heavier loads and have average rotational flexibility.

Terling bearings: Terling is a special engineering plastic, suitable for wet and corrosive places, with average rotation flexibility and high resistance.

Rivets: Rivets are mainly used for some smaller caster models. Because the casters are too small to install bearings in them, rivets can only be used as the central axis for the rotation of the casters. When in use, the swinging clearance of the wheel is relatively large, and the force load is small, which is suitable for some relatively small handicrafts.

Plane pressure bearing: suitable for occasions with extra high load and high speed. Therefore, it is often used for some special heavy machinery.

(3)Brake device

Due to the wear and tear of the casters due to prolonged use, the function of the casters may be reduced, so please keep an eye on it.

Stainless steel casters will reduce their anti-rotation effect after a period of use.

Regarding braking performance, please use other braking methods, such as caster brakes, ground anti-slip, etc.

(4) Environmental conditions for using casters

The use environment of stainless steel casters is set in the indoor environment under normal temperature, so try to avoid using them in special environments, such as high temperature, low temperature, high acidity, high alkalinity, multi salinity, chemical solvents, oil, sea water and liquid medicine, which will reduce the effectiveness of casters.

When using, it is necessary to separate various situations and provide other reliable measures, such as the material of metal utensils, the material of casters, the material of lubricating oil and so on. Balance it all out, and take into account that some materials can stain the floor.

(5)About speed

The requirements for the speed of stainless steel casters are: in the normal temperature environment, on a flat ground, the diameter is below Φ75mm, not higher than the walking speed of 2km/h, the diameter is below Φ100mm, not higher than the walking speed of 4km/h, and there are certain stops. In the working state, please avoid the continuous or non-stop use of the caster hair pad.

(6)About flexibility

Casters should be flexible, easy and durable, and their rotating parts (bracket rotation, wheel rolling) should be made of materials with low friction coefficient or accessories assembled after special processing.

Such as ball bearings or hardened.

The larger the eccentricity of the bracket, the more flexible the steering is, but the bearing capacity is relatively reduced.

The larger the diameter of the wheel, the less effort is needed to push and the better the protection of the ground. The larger the wheel turns slower than the smaller one, it is not easy to heat and deform, and it is more durable. Under the condition that the installation height allows, choose the wheel with the largest diameter as much as possible.

Eccentricity refers to the distance between the steering axis of the bracket and the rotation axis of the single wheel.

How to Install Casters?

Please observe the following for the installation of casters:

1. Please use the same series of products.

2. When installing on fixed casters, install it in a horizontal state.

3. For movable casters, please keep the rotating shaft in a vertical state for installation.

4. After confirming that the connection parts are fixed, select screws, nuts, washers, etc. of suitable size, insert them into the mounting holes, and tighten the casters until there is no gap to avoid loosening. In particular, when screwing in, please tighten the hexagon with an appropriate torque. Avoid over-screwing and causing the rotating shaft to expand and cause breakage.

When installing the casters with double brakes, please avoid screwing in the brakes when the brakes are turned on, because that will cause damage to the brakes, deformation and performance deterioration.

Start working with us today to make your stainless steel casters business more profitable!

We are here for all your business needs and questions.