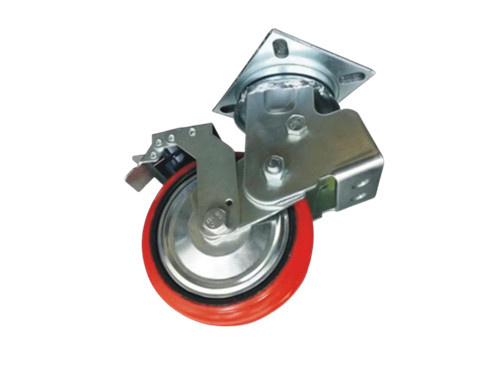

Spring-Loaded Industrial Casters (500kg)

Load Capacity: ≤500kg

Installation Method: Top Plate

Installation Size: (98-112)x(72-84)mm

Top Plate Size: 138x110x6mm

Bolt Hole Size: 14.3mm

Load Height: 253mm

Wheel Diameter: φ200xW51mm

Wheel Material: High-Tech Moldon PU

Bracket Type: Swivel/Rigid

Bracket Material: Metal

More Items You Might Request

| Wheel Diameter | Tread Width | Load Capacity | Wheel Material | Bracket Type | Installation Type | Installation Size | Overall Height |

|---|---|---|---|---|---|---|---|

| φ125mm | 50mm | 400kg | High-tech Moldon PU+Iron Core | Swivel/Rigid | Top Plate | (98-112)x(72-84)mm | 210mm |

| φ150mm | 51mm | 450kg | High-tech Moldon PU+Iron Core | Swivel/Rigid | Top Plate | (98-112)x(72-84)mm | 220mm |

| φ200mm | 51mm | 500kg | High-tech Moldon PU+Iron Core | Swivel/Rigid | Top Plate | (98-112)x(72-84)mm | 253mm |

Features

Spring-loaded industrial casters are a type of caster that are designed to provide extra support and shock absorption for heavy loads. These casters feature a spring-loaded suspension system that helps to absorb shocks and reduce vibrations when moving heavy objects. Some of the key features of spring-loaded industrial casters include:

- Load capacity: Spring-loaded industrial casters are capable of handling heavy loads ranging from several hundred pounds to several tons, depending on the specific model.

- Shock absorption: The spring-loaded suspension system helps to absorb shocks and reduce vibrations, making it easier to move heavy loads without damaging them or the floor.

- Swivel locking: Many spring-loaded industrial casters come with a swivel locking mechanism that allows you to lock the caster in place once you’ve positioned the load.

- Durability: These casters are typically made from high-quality materials like steel, aluminum, or polyurethane, which makes them resistant to wear and tear and ensures they can withstand heavy use.

- Versatility: Spring-loaded industrial casters can be used in a wide range of applications, including manufacturing, warehousing, and transportation.

- Maneuverability: The swivel design of these casters allows for easy maneuverability, even in tight spaces.

Applications

Spring-loaded industrial casters have a variety of applications in different industries due to their ability to handle heavy loads and provide shock absorption. Here are some common applications of spring-loaded industrial casters:

- Manufacturing: In manufacturing facilities, spring-loaded industrial casters are used to transport heavy equipment, machinery, and products. The casters allow for easy movement of heavy loads while protecting the equipment and the floor from damage.

- Warehousing: Spring-loaded industrial casters are commonly used in warehouses for moving heavy pallets, crates, and containers. The shock-absorbing properties of the casters help to protect the contents of the load and reduce the risk of damage.

- Aerospace: The aerospace industry uses spring-loaded industrial casters to move heavy aircraft components, such as engines and landing gear. The casters help to protect the delicate equipment and ensure safe transportation.

- Automotive: In the automotive industry, spring-loaded industrial casters are used to move heavy vehicle parts and components, such as engines and transmissions. The casters provide shock absorption to protect the parts and make transportation easier.

- Heavy equipment: Spring-loaded industrial casters are often used in the construction industry to move heavy equipment, such as cranes and bulldozers. The casters help to reduce vibrations and protect the equipment during transportation.

- Medical: In hospitals and medical facilities, spring-loaded industrial casters are used to move heavy medical equipment, such as X-ray machines and hospital beds. The shock-absorbing properties of the casters help to protect the equipment and ensure safe transportation.